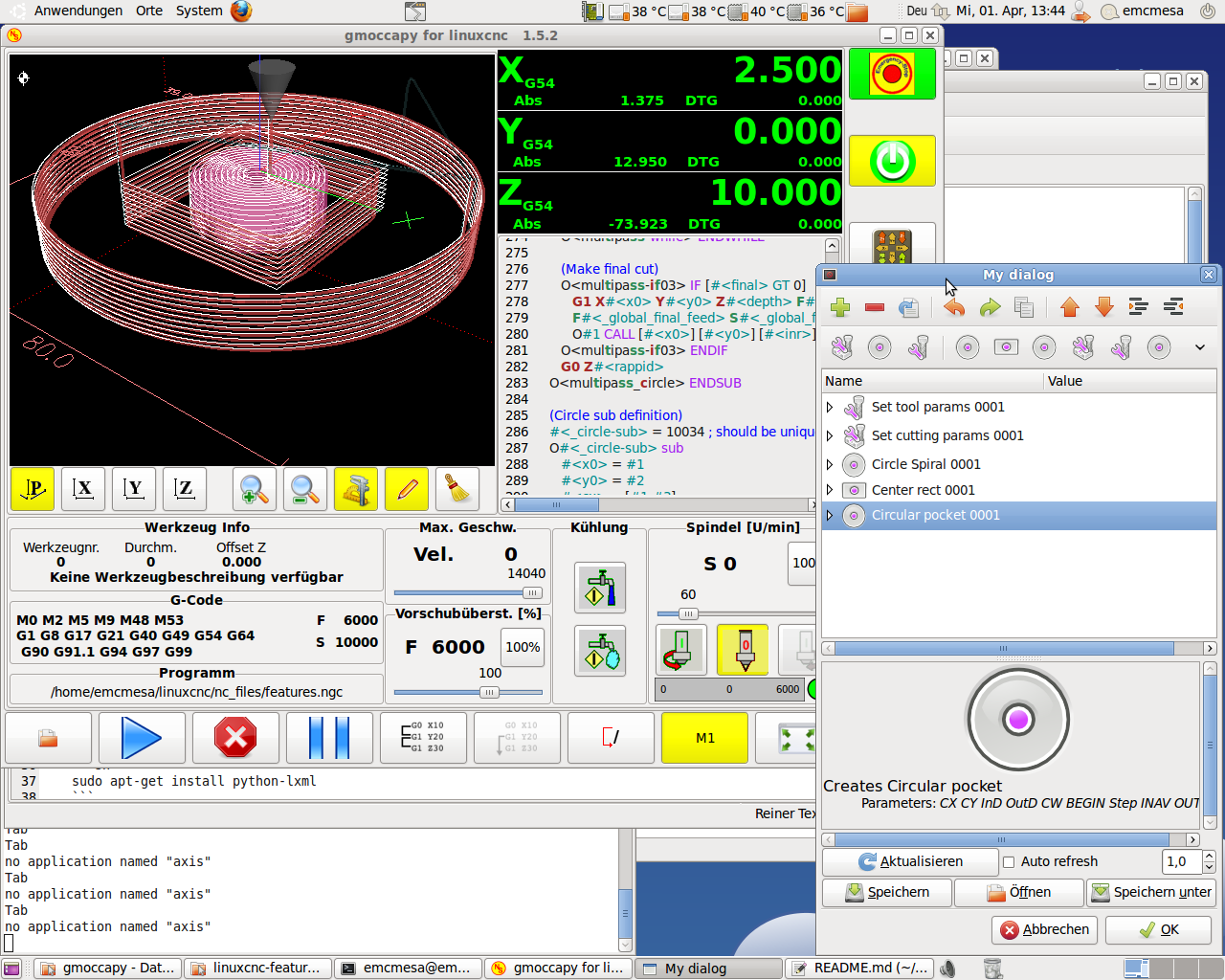

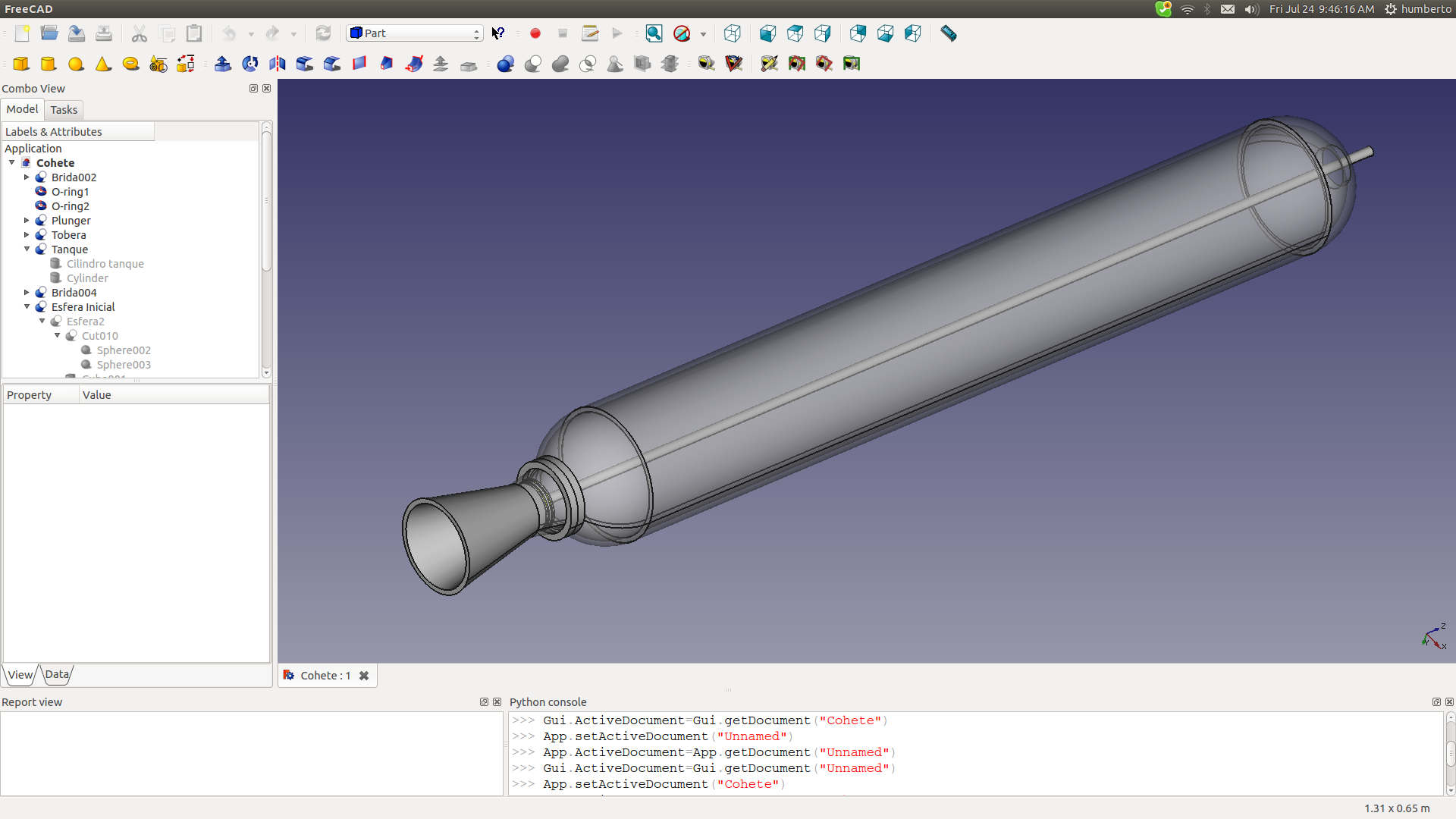

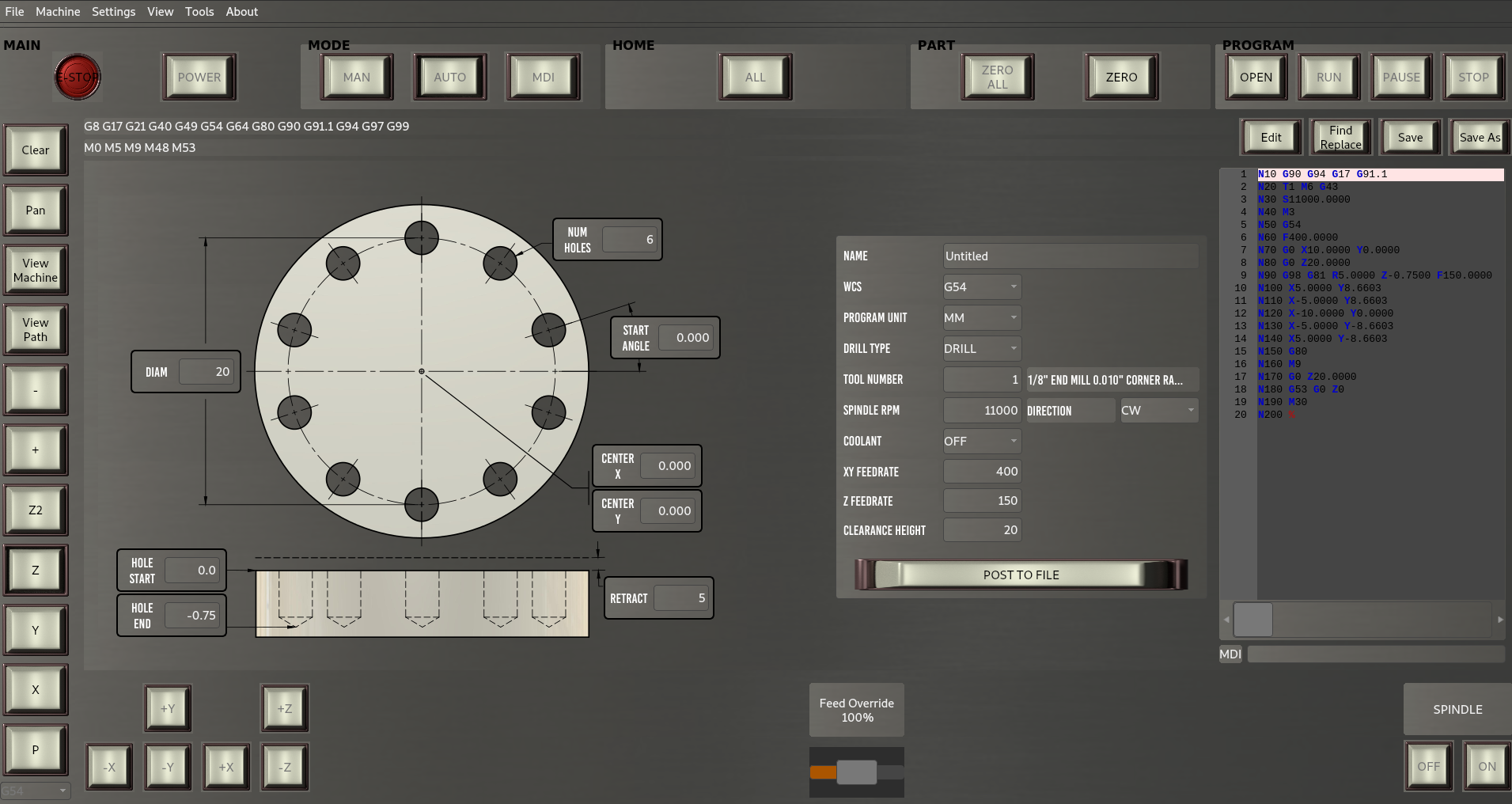

Not that I personally need this "professional feature" of controlling / tweaking the run of the program at the machine (instead of regenerating the gcode), but this realization hurts my heart. In other words: Is the "correct working approach" to make sure that radius-compensation is always turned off on my machine and let Path generate the path for fixed tool information? Anyhow, you're the one at the control and making the final choice. For that reason, I believe programming a Path for cutter "center" position is safest. If you have the system generate a number of points which all end up on top of each other, your control might not be able to distinguish (zero-distances involved) which side of the Path is on the right side, and the cutter might gouge the part. One thing I would have you think about is the number of path points at sharp corners, whether you are doing an arc around that corner or if you are cutting past to tangent for the next cut. The way I see it, using the register for the "correction" value might be a safer approach, but you might have a different opinion on that, given what you are asking for (desire to use actual radius). With that approach, you don't need to have a separate step of generating code other than the default Path values generated by FreeCAD for the "ideal" tool. Normally, the compensation register is for the difference between the "design value" and the "actual" value of the tool's radius. If I understood correctly, you wish to program the cutter's measured radius directly into the CNC. Is it programmed into the control ahead of time or is it supposed to be passed in each Feed move? What you describe is very similar to LinuxCNC cutter compensation but you didn't say where the R word comes from. They are only sequenced and converted to the final gcode.

The Path commands are not recomputed at postprocessing. It isn't possible for FreeCAD to simulate or visualize correctly the gcode that gets modified downstream. Also some profiles could be intended to be without compensation (in FreeCAD and maschine code)įreeCAD's visualization and simulation is of the Path Commands that it is generating.

But with many operations it becomes unhandy and error prone. Only the code for the maschine should have no compensation.įor sure, i could uncheck before postprocessing and than check again. During design I want compensation to be active zu see how the path will look like and to have a proper simulation.

0 kommentar(er)

0 kommentar(er)